Our Concrete Floor Coating Process

A simple 4-step process to durable, beautiful floors completed in a single day.

Step 1: Prepare the Concrete

We begin by thoroughly prepping your floor using industrial grinders and HEPA vacuums. This dust-controlled process opens the concrete pores, removes imperfections, and creates a strong foundation for a long-lasting coating. During prep, we also repair damaged areas by opening cracks, filling them with a powerful bonding agent, and smoothing out pits or spalling to ensure a flawless, even surface.

Step 2: Apply the Basecoat

A self-leveling concrete floor coating base is applied to penetrate the pores and bond with the surface. This layer ensures a smooth, even foundation that enhances adhesion for the next steps.

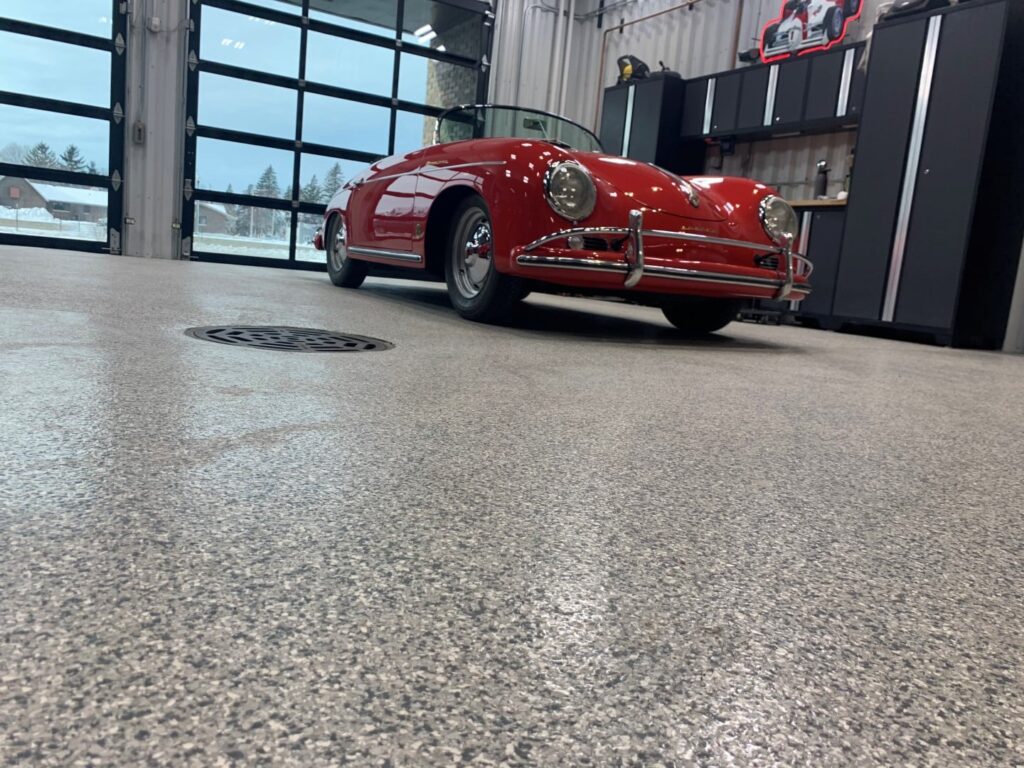

Step 3: Add Color & Flakes

Decorative color chips are broadcast across the floor in your choice of colors and blends. This creates a unique, textured look while adding depth, style, and slip-resistant properties.

Step 4: Seal with Topcoat

Finally, we apply a durable topcoat that protects against UV rays, chemicals, stains, and abrasions. Your floor is ready for foot traffic in just a few hours and vehicle use within 48 hours.

Ready to Upgrade Your Floor with a Concrete Floor Coating?

Schedule your free on-site estimate today and see how Integrity Concrete Coatings can transform your floors in just one day.